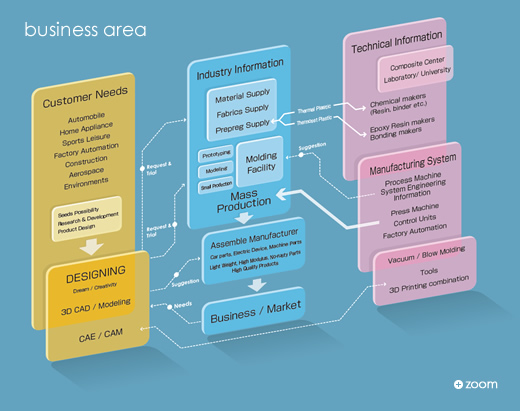

Magic box JP is completely Independent.

We can offer neutral information simply because we do not have our own manufacturing facility equipment toward the company.

We can supply the pure direction which client needs.

We can offer neutral information simply because we do not have our own manufacturing facility equipment toward the company.

We can supply the pure direction which client needs.

Magic box JP performs wide consulting about the advanced composite materials including the carbon composite designing and process engineering.

It is 30 years soon since the founder met a carbon material in the FRP product manufacturing facility for the motorcycle race in 1984 at the time of the Osaka University of Arts design, industrial design specialty.

He mastered a basic molding technology of the FRP for school days and wore "every duty except the molding work of the CFRP factory" after industrial design office duty afterwards in an original FRP product production sales company for ten years. As well as a business window, materials procurement for company factories, the plan of the OEM product, purchasing / sale, the reclamation / management of the cooperation factory, the cooperation with the foreign countries racing team, country tip parts procurement except the CFRP of the Moto-GP level are them. Meanwhile, the thing which he got is an intelligence technology and communicative competence.

He started his own composite designing firm in 2004 and there was the request of client company. He had overseas materials manufacturers, production facilities and cooperation for the research of the mass production technology of the CFRP and got friends who had the high production technology that there was not of meeting you in Japan afterwards.

In Japan, materials, the production engineering about the composite materials every day and cooperate with each players. The circle is enlarged now.

It is 30 years soon since the founder met a carbon material in the FRP product manufacturing facility for the motorcycle race in 1984 at the time of the Osaka University of Arts design, industrial design specialty.

He mastered a basic molding technology of the FRP for school days and wore "every duty except the molding work of the CFRP factory" after industrial design office duty afterwards in an original FRP product production sales company for ten years. As well as a business window, materials procurement for company factories, the plan of the OEM product, purchasing / sale, the reclamation / management of the cooperation factory, the cooperation with the foreign countries racing team, country tip parts procurement except the CFRP of the Moto-GP level are them. Meanwhile, the thing which he got is an intelligence technology and communicative competence.

He started his own composite designing firm in 2004 and there was the request of client company. He had overseas materials manufacturers, production facilities and cooperation for the research of the mass production technology of the CFRP and got friends who had the high production technology that there was not of meeting you in Japan afterwards.

In Japan, materials, the production engineering about the composite materials every day and cooperate with each players. The circle is enlarged now.